Zone of Interest Clip A Comprehensive Guide

Zone of interest clip, a versatile tool with applications spanning engineering, photography, and data analysis, offers precise control and focus. This guide delves into its history, technical specifications, practical uses, design considerations, and safety precautions, equipping you with a comprehensive understanding of this intriguing tool. From its humble beginnings to its modern adaptations, we explore the evolution of the zone of interest clip, and examine its impact across various industries.

Understanding the nuances of zone of interest clips is crucial to maximizing their potential. Different types cater to specific needs, offering unique functionalities. This exploration highlights the key characteristics of these tools and explores their use in diverse contexts. The various materials, manufacturing processes, and design considerations are also examined to ensure optimal performance.

Defining “Zone of Interest Clip”

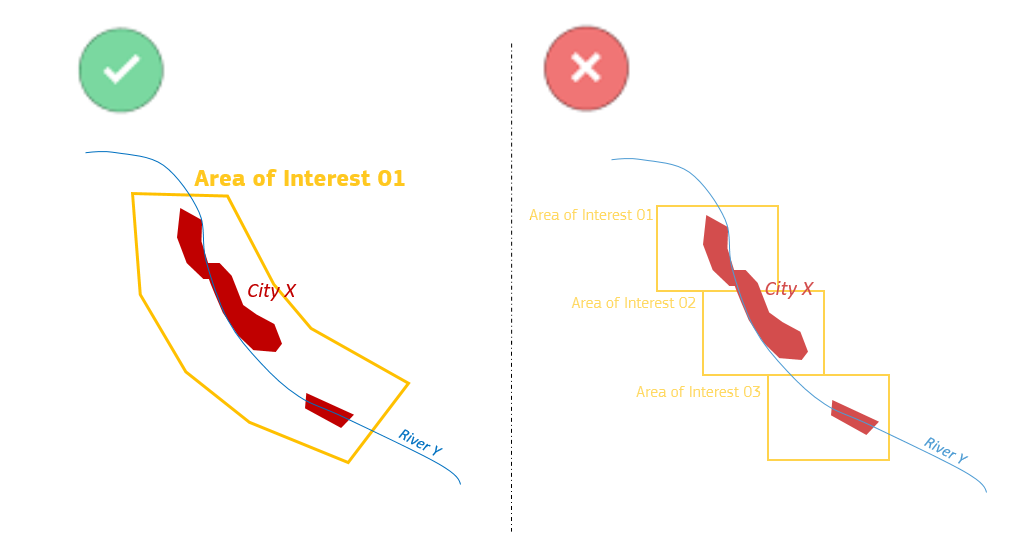

A “zone of interest clip” is a critical concept across diverse fields, from engineering and photography to data analysis. It essentially highlights a specific area within a larger context that holds particular significance for the task at hand. This could be a region of interest in an image, a critical section of a mechanical design, or a dataset subset containing valuable insights.

Understanding the definition, types, and applications of “zone of interest clips” is crucial for efficient analysis and problem-solving.

Definition and Scope

A zone of interest clip, in its broadest sense, is a delimited portion of a larger entity, whether an image, a dataset, or a physical object. This focused area is chosen for its inherent value or potential to reveal crucial information. This approach is particularly valuable when dealing with complex systems or large datasets, as it allows analysts to concentrate their efforts on the most pertinent elements.

The definition transcends specific fields and is adaptable to various contexts.

Types and Variations

The nature of a “zone of interest clip” varies according to the context. In engineering, it might represent a critical stress region in a component, a specific area for material analysis, or a sensor data collection zone. In photography, it might be a specific area of a landscape image, or a detailed view of a subject. In data analysis, it might be a portion of a dataset with high variability or a group of data points showing specific patterns.

The specific characteristics of a zone of interest clip are defined by the context and the objectives of the analysis.

Applications Across Contexts

- In engineering, a zone of interest clip can be used to pinpoint critical stress points in a structural component, allowing engineers to design stronger, more durable structures. For example, a zone of interest clip in a bridge design might reveal areas susceptible to fatigue cracks. This focus helps engineers concentrate on the most vulnerable regions to improve design robustness.

That recent zone of interest clip I saw got me thinking about the current Gaza cease-fire situation, particularly the complex interplay between Russia and NATO, as detailed in this article about gaza cease fire russia nato. It’s fascinating how global events can impact even seemingly localized issues like a zone of interest clip. Hopefully, this will provide more context for my future analysis of the clip.

- In photography, a zone of interest clip isolates a particular subject or scene element, allowing for enhanced detail and focus. A macro photograph of a flower, for example, might use a zone of interest clip to highlight the intricate details of a petal.

- In data analysis, a zone of interest clip is used to identify trends, anomalies, and patterns in data. Analyzing financial data to identify fraudulent activity is a common application. A zone of interest clip might focus on a specific period in the financial record showing unusual transaction patterns.

Characteristics of a Zone of Interest Clip

The characteristics that define a “zone of interest clip” depend entirely on the specific context. However, common traits include:

- Delimitation: The zone must be clearly defined and bounded, distinguishing it from the surrounding context.

- Relevance: The zone must hold significance or relevance to the analysis or task at hand. This is the defining feature.

- Focus: The zone should be focused on a specific aspect or element within the larger entity.

Comparison Table

| Context | Description | Applications |

|---|---|---|

| Engineering | A region of interest within a larger system, such as a component or structure, where specific characteristics (e.g., stress, material properties) are of interest. | Structural analysis, component design, material testing. |

| Photography | A region of interest within an image, highlighting a specific subject or detail. | Macro photography, landscape photography, portraiture. |

| Data Analysis | A subset of data with specific characteristics (e.g., high variability, unusual patterns) that is selected for further investigation. | Fraud detection, anomaly detection, trend analysis. |

Historical Context and Evolution: Zone Of Interest Clip

The concept of “zone of interest clips” is not as straightforward as a precise historical entity. While the underlying principle of focusing on specific segments of a larger body of information exists in various forms across different historical periods, the explicit labeling and formalized application of “zone of interest clips” as a distinct methodology emerged more recently. This evolution is closely tied to advancements in information technology, media consumption patterns, and the increasing need for efficient information retrieval.The idea of selectively focusing on key parts of a subject or message has existed for centuries.

Think of historical accounts or summaries that highlighted crucial events, or the use of excerpts from literary works to convey a particular theme. These approaches represent early precursors to the modern concept.

Early Forms and Precursors

Early examples of focusing on specific areas of interest within a larger body of material can be found in various historical contexts. For instance, summary reports, abstracts, and even the meticulous cataloging of historical documents can be viewed as early forms of selecting “zones of interest”. In essence, humans have always sought to distill vast amounts of data into manageable chunks for focused analysis and understanding.

Early examples included selective copying of texts, summaries of historical events, and hand-drawn maps highlighting areas of strategic importance.

Key Milestones in Evolution

A timeline showcasing key milestones in the development of “zone of interest clips” is difficult to establish due to the gradual nature of this evolution. The emergence of digitized information and online archives played a crucial role in shaping the current understanding and application of the concept. The proliferation of video editing software and online video sharing platforms further enabled the extraction and dissemination of specific video segments.

- Pre-20th Century: Selective copying and summarization of information were prevalent, but lacked the precise digital tools and methods of modern “zone of interest clips”.

- Early 20th Century: The rise of radio and film provided a platform for targeted information dissemination, though the tools for precise clipping were still limited.

- Mid-20th Century: The advent of videotape and early editing software allowed for more precise extraction of video segments, although the concept wasn’t explicitly named or formalized as “zone of interest clips”.

- Late 20th Century: The digital revolution led to the widespread availability of digital video editing tools and online video platforms, enabling the easier creation and sharing of specific video segments. This period marked the beginning of the formalization of the concept.

- 21st Century: Advancements in AI and machine learning technologies are enabling automated tools to identify and extract “zones of interest” from various types of media, expanding the scope and application of the concept.

Comparison with Modern “Zone of Interest Clips”

Early methods of extracting zones of interest often relied on manual processes. Modern methods leverage sophisticated software, AI, and machine learning to automatically identify and extract relevant segments, often based on pre-defined criteria or user input. This automation significantly increases efficiency and accessibility. The tools for creating, accessing, and sharing these clips are vastly different, making the modern approach far more streamlined and scalable.

Technical Specifications and Functionality

Zone of interest clips, while seemingly simple, play a crucial role in various applications by precisely defining and isolating areas of focus. Their effectiveness hinges on the careful consideration of technical specifications and how these translate into specific functionalities. Understanding the diverse ways these clips are employed in different contexts provides valuable insights into their versatility.Understanding the technical details of zone of interest clips, such as material composition, dimensional tolerances, and the mechanisms of engagement, is essential for selecting the appropriate clip for a particular application.

The functionality of these clips depends on their ability to precisely delineate and maintain the designated zone of interest.

Material Specifications

Different materials are used for zone of interest clips depending on the application. Aluminum alloys, often chosen for their lightweight nature, are frequently used in consumer electronics. Stainless steel, known for its corrosion resistance, is preferred in industrial settings where harsh environments are common. The choice of material impacts the durability, weight, and cost of the clip.

Furthermore, the material’s thermal conductivity can be a factor in certain applications.

Dimensional Tolerances and Mechanisms

Precise dimensional tolerances are critical for ensuring the clip accurately defines the zone of interest. Variations in dimensions can lead to misalignment or inaccurate targeting. Mechanisms for engagement and release vary depending on the application. Some clips employ a simple latching mechanism, while others use more sophisticated spring-loaded systems for secure retention. These mechanisms influence the speed and ease of use of the clip, as well as the clip’s ability to maintain the zone of interest over time.

Functionality in Different Applications

Zone of interest clips are used in a multitude of applications, ranging from medical imaging to industrial automation. In medical imaging, these clips precisely define the area of interest for analysis, ensuring accurate data collection. In industrial automation, zone of interest clips help focus sensors on specific regions, allowing for precise measurements and control. Furthermore, the ability to quickly and easily adjust the zone of interest is crucial for adaptability in dynamic environments.

Integration into Larger Systems

Zone of interest clips are often integrated into larger systems through standardized interfaces. This allows for easy interchangeability and compatibility with various components. These interfaces, typically mechanical connections, are designed for smooth and efficient operation. A well-integrated clip ensures seamless interaction with the overall system.

Examples of Specific Results

Consider a camera system used for quality control in a manufacturing plant. A zone of interest clip is used to precisely target a specific component on an assembly line. This ensures the camera captures the critical dimensions and features of the part, allowing for immediate feedback and adjustments to the manufacturing process. This exemplifies how these clips improve the efficiency and accuracy of automated systems.

Another example includes a laser scanner in a warehouse. A zone of interest clip focuses the scanner’s beam on the specific barcode for efficient and reliable inventory management.

Practical Applications and Use Cases

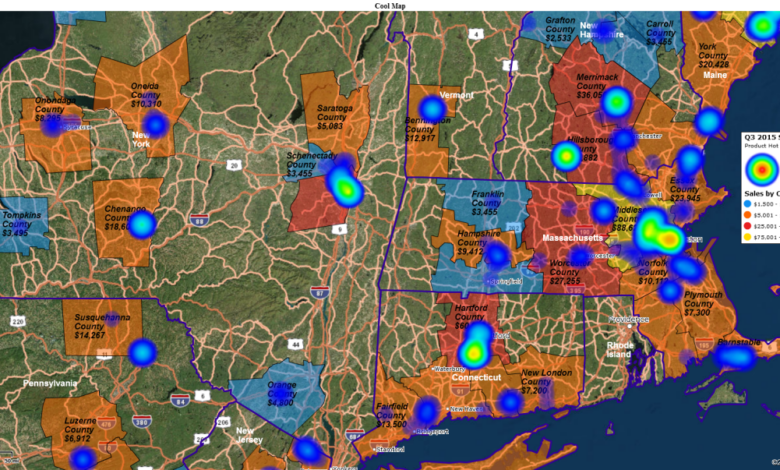

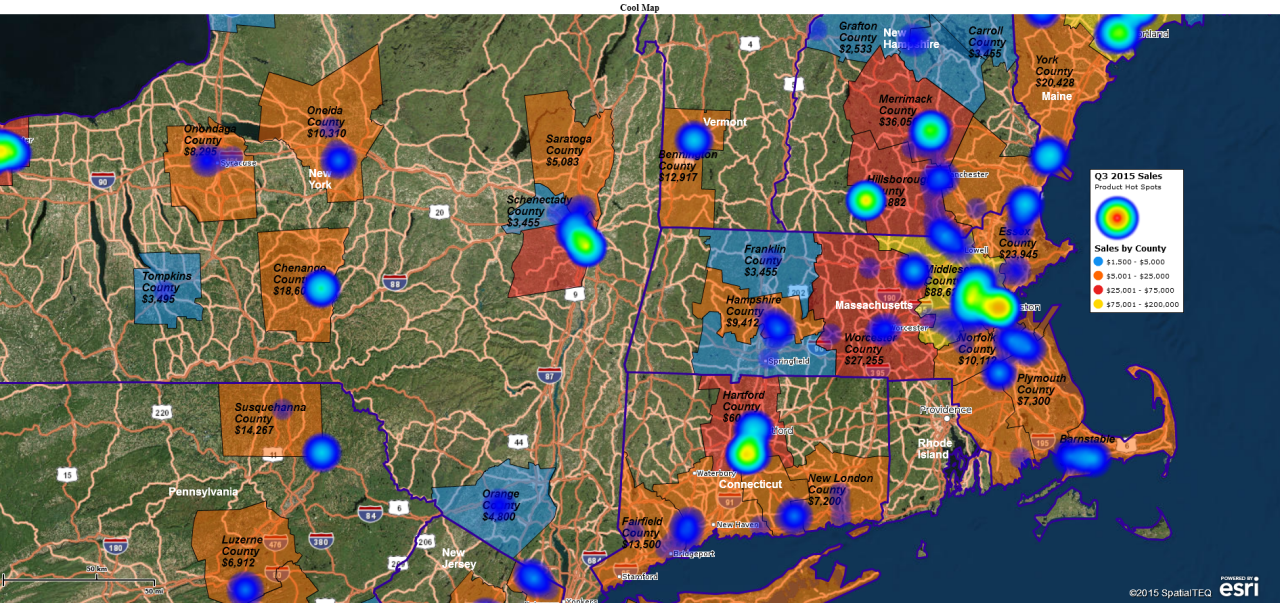

Zone of Interest (ZoI) clips, a powerful tool for video analysis, have found diverse applications across numerous fields. From surveillance and security to scientific research and entertainment, their ability to focus on specific regions within a video stream opens up new possibilities for data extraction and understanding. This section delves into the practical uses of ZoI clips, illustrating how they address specific problems and improve efficiency in various sectors.

Surveillance and Security

ZoI clips excel in security systems by concentrating on predefined areas of interest. For instance, a retail store can utilize ZoI clips to monitor high-theft areas, like entrances and display cases. The system can automatically record footage from these specific zones, triggering alerts for unusual activity, reducing the need to review extensive footage and increasing response times. Similarly, in public spaces, ZoI clips can be used to monitor crowded areas or vulnerable points like ATMs, enhancing safety and security measures.

Scientific Research

ZoI clips are instrumental in scientific research, enabling focused data collection and analysis. In wildlife studies, researchers can utilize ZoI clips to track the movement and behavior of specific animals within a designated area. This method allows for detailed observation of animal interactions, foraging patterns, and social behaviors without the need to analyze the entire video stream. Similarly, in medical research, ZoI clips can be used to analyze microscopic images, isolating regions of interest to study cellular structures and processes.

Entertainment and Sports Analysis

In the entertainment industry, ZoI clips facilitate the analysis of specific performances or events. For example, in sports broadcasting, ZoI clips can focus on key players, highlighting their actions and interactions, providing viewers with detailed insights into gameplay. Similarly, in film production, ZoI clips can be used to analyze actor movements and expressions, improving the quality of performance.

Zone of interest clips are totally fascinating, especially when you consider how they’re used in the fashion world. The recent Saint Laurent Dior Paris Fashion Week shows just how designers are incorporating these unique elements. saint laurent dior paris fashion week showcased some truly innovative ways to use them, pushing the boundaries of what’s possible. Ultimately, these clips are a powerful tool for capturing attention and elevating any look.

This allows for quicker editing and enhanced creative direction.

Zone of interest clips are a game-changer for capturing specific moments in a video. They’re great for highlighting key actions or reactions. For instance, the recent drama surrounding Felicia Snoop Pearson and Ed Burns’s wire incident, as detailed in this article felicia snoop pearson ed burns wire , could have benefited from a zone of interest clip to focus on the key moments of the story.

Ultimately, zone of interest clips are a powerful tool for any video editor looking to make their content more engaging.

Traffic Monitoring and Management

ZoI clips are valuable in traffic management systems to analyze congestion patterns and optimize traffic flow. For example, by focusing on specific intersections or highways, the system can gather data on traffic volume, speed, and congestion levels. This data allows traffic engineers to make informed decisions about adjusting traffic signals, rerouting traffic, and implementing measures to alleviate congestion.

This can lead to reduced travel times, lower fuel consumption, and improved overall traffic efficiency.

Comparison of ZoI Clips Based on Use Cases and Performance

| Use Case | ZoI Clip Type | Performance Metrics (Example) | Advantages | Disadvantages |

|---|---|---|---|---|

| Surveillance (Retail Store) | Motion-activated, pre-defined zones | High trigger rate, low false positives | Reduced review time, faster response to theft | Potential for missed events outside defined zones |

| Wildlife Studies | Object-tracking, animal-specific | High accuracy in animal location, behavior tracking | Detailed analysis of animal behavior | Potential for bias in selection criteria |

| Traffic Monitoring | Automated data collection, intersection-focused | High volume data collection, real-time analysis | Optimized traffic flow, reduced congestion | High data volume requires advanced processing |

Advantages and Disadvantages of Using ZoI Clips

The use of ZoI clips presents several advantages, including increased efficiency in data collection and analysis, reduced manual effort, and focused attention on key areas. However, limitations include potential for missing important events outside the designated zones, and the need for careful pre-selection of zones to avoid bias. The choice to use ZoI clips depends heavily on the specific application and the desired level of detail.

Materials and Manufacturing Processes

The creation of a “zone of interest clip” hinges critically on the selection of appropriate materials and the precision of the manufacturing process. These choices directly impact the clip’s functionality, durability, and overall performance in its intended application. The material properties determine the clip’s resistance to wear, corrosion, and environmental factors, while the manufacturing process dictates the clip’s dimensional accuracy and structural integrity.

Ultimately, the combination of material and manufacturing technique dictates the clip’s suitability for various tasks.Understanding the interplay between material selection and manufacturing processes is paramount for optimizing the performance and longevity of these clips. The ideal material should exhibit strength, flexibility, and resilience to the specific operational conditions. The manufacturing process must ensure precise dimensions, consistent quality, and the desired structural integrity to maintain the clip’s functionality over time.

Materials Used

A variety of materials can be employed in the construction of zone of interest clips, each offering distinct advantages and disadvantages. Common choices include metals like stainless steel, aluminum alloys, and specialized polymers. The selection often depends on factors like the anticipated stress levels, the operating environment, and the desired cost-effectiveness.

- Stainless Steel: Known for its corrosion resistance, strength, and durability, stainless steel is a popular choice in demanding environments. Its high tensile strength makes it suitable for applications requiring significant load-bearing capabilities. Specific grades of stainless steel, like 304 or 316, offer varying degrees of corrosion resistance and strength, influencing the selection based on the specific use case.

- Aluminum Alloys: Aluminum alloys are favored for their lightweight properties and good corrosion resistance, making them suitable for applications where weight is a concern. The alloy composition influences its strength and hardness, allowing tailoring for specific requirements.

- Polymers: Polymers like acetal or polycarbonate are sometimes used for their exceptional impact resistance and chemical inertness. These materials are often chosen for applications where a combination of flexibility and toughness is desired.

Manufacturing Processes, Zone of interest clip

Various manufacturing techniques can be employed to create zone of interest clips. The chosen process dictates the achievable precision, production volume, and cost. Common techniques include stamping, injection molding, and machining.

- Stamping: Stamping is a high-volume manufacturing method ideal for creating complex shapes from sheet metal. It’s cost-effective for large-scale production, and the precision achieved depends on the tooling used. Stamping is a good option for stainless steel clips needing precise dimensions.

- Injection Molding: Injection molding is often used for creating clips from polymers. This process involves melting the polymer and injecting it into a mold, allowing for the creation of intricate shapes and complex designs. Injection molding is well-suited for manufacturing polymer clips requiring high dimensional accuracy and consistency.

- Machining: Machining, utilizing techniques like turning and milling, is employed for creating intricate shapes and high-precision parts. This process is often chosen when unique geometries or exceptionally tight tolerances are needed. Machining is typically used for producing small batches of custom-designed clips.

Factors Influencing Material and Process Selection

The choice of material and manufacturing process isn’t arbitrary; it’s a careful consideration of various factors. The intended application, budget constraints, required strength, environmental conditions, and production volume are crucial factors.

- Application Requirements: The specific requirements of the application significantly impact the selection of materials and manufacturing processes. For example, a clip used in a harsh chemical environment necessitates a corrosion-resistant material, like stainless steel.

- Budget Considerations: Cost is a primary driver in material and manufacturing decisions. Stainless steel, while durable, might be more expensive than an aluminum alloy for the same application. Manufacturing processes also have varying costs, with stamping generally being more economical for high-volume production.

- Strength and Durability: The anticipated stress and load on the clip dictate the need for strong materials like stainless steel. High-strength alloys might be required for applications involving heavy loads, while polymers are often chosen for flexibility and impact resistance.

- Environmental Conditions: Exposure to extreme temperatures, chemicals, or harsh weather conditions influences the selection of materials resistant to these factors. Corrosion-resistant metals are crucial in environments with high humidity or chemical exposure.

- Production Volume: Large-scale production favors cost-effective processes like stamping, while smaller batches might benefit from more precise but potentially more expensive machining.

Material Property Comparison

| Material | Strength (MPa) | Corrosion Resistance | Cost | Typical Applications |

|---|---|---|---|---|

| Stainless Steel 304 | ~200-300 | Good | Medium | General-purpose clips, demanding environments |

| Aluminum Alloy 6061 | ~200-300 | Good | Low | Lightweight clips, applications where weight is critical |

| Acetal Resin | ~30-60 | Excellent | Low | Clips requiring impact resistance, chemical inertness |

Design Considerations and Optimization

Crafting effective “zone of interest” clips requires careful consideration of various factors to ensure optimal performance and functionality. A well-designed clip not only enhances the user experience but also streamlines the overall process. This involves understanding the intended application, selecting the right materials, and meticulously optimizing the design for efficiency.

Key Design Considerations

The success of a “zone of interest” clip hinges on several critical design considerations. These include the material selection, the clip’s geometry, the attachment mechanism, and the overall size and weight. A comprehensive understanding of these factors allows for the creation of clips tailored to specific needs.

Factors Influencing Efficiency and Effectiveness

Several factors directly influence the efficiency and effectiveness of “zone of interest” clips. These include the material’s strength and elasticity, the clip’s surface area and geometry, and the method of attachment. Consideration of these factors ensures optimal performance and longevity of the clip in various environments.

Methods for Optimizing Design

Several methods can be employed to optimize the design of “zone of interest” clips for specific applications. One crucial approach is rigorous prototyping and testing, allowing for iterative refinement based on real-world performance data. Analyzing the stresses and strains on the clip under different operational conditions is critical for identifying potential failure points. Employing finite element analysis (FEA) can predict the behavior of the clip under various loads, allowing for the creation of a more robust and efficient design.

Design Parameters and Their Impact on Performance

| Design Parameter | Impact on Performance |

|---|---|

| Material Strength | Higher strength materials result in greater resistance to deformation and breakage, leading to a longer lifespan. Examples include using stainless steel for harsh environments or specialized polymers for lighter-weight applications. |

| Surface Area | Larger surface areas can increase friction and ensure secure attachment, but also increase the potential for material stress. Optimizing surface area is crucial to maximize grip while minimizing strain. |

| Geometry | Specific shapes and curves influence the clip’s ability to conform to the target area and distribute forces effectively. Geometric design choices directly affect the clip’s stability and its ability to remain securely in place. |

| Attachment Mechanism | The method of attachment (e.g., mechanical interlocking, adhesive bonding) impacts the clip’s security and ease of use. Choosing the right mechanism is critical for ensuring reliable and convenient attachment in various scenarios. |

| Size and Weight | Size and weight are important for usability and portability. A balance must be struck between sufficient size for reliable engagement and a manageable weight to prevent user fatigue. For example, in mobile applications, minimizing weight is essential. |

Troubleshooting and Maintenance

Zone of Interest (ZOI) clips, crucial components in various applications, can experience issues over time. Understanding common problems and implementing proper maintenance procedures is essential for ensuring reliable performance and extending their lifespan. This section details troubleshooting steps and maintenance strategies for different types of ZOI clips.Troubleshooting ZOI clips involves identifying the root cause of malfunctions. Often, a systematic approach, combining visual inspection with targeted testing, is key to effective problem-solving.

Proper maintenance, performed regularly, can prevent potential issues and maintain optimal performance.

Common Issues and Solutions

A thorough understanding of potential problems allows for proactive solutions. Several issues can arise in ZOI clips, including but not limited to material degradation, improper installation, and environmental factors.

- Material Degradation: Over time, the materials used in ZOI clips can degrade due to exposure to harsh environments, UV radiation, or chemical contaminants. This degradation manifests as cracking, discoloration, or loss of elasticity. Addressing this involves using materials resistant to the specific operating conditions, and implementing protective coatings.

- Improper Installation: Incorrect installation can compromise the ZOI clip’s functionality and lead to premature failure. This includes inadequate clamping force, misalignment, or improper positioning of the clip within the application. Correct installation procedures, including torque specifications and alignment guidelines, are crucial to avoid these issues.

- Environmental Factors: Exposure to extreme temperatures, humidity, or corrosive substances can impact the performance of ZOI clips. These factors can lead to material weakening, loss of adhesion, or corrosion. Implementing appropriate environmental protection measures and using suitable materials for the operating conditions can mitigate these issues.

Maintenance Procedures for Different Types

Different types of ZOI clips require specific maintenance routines.

- Mechanical ZOI Clips: Regular visual inspection for signs of wear and tear, such as cracks, deformation, or corrosion, is critical. Cleaning the clip and its mounting surfaces to remove debris is also essential. Periodic re-tightening of mounting screws or fasteners is often necessary.

- Electromagnetic ZOI Clips: Regular checks for proper electromagnetic field strength and proper functioning of the electrical components are important. Cleaning the clip and surrounding components from dust or debris is also a critical step. Consult the manufacturer’s guidelines for specific maintenance instructions.

Troubleshooting Table

This table provides a quick reference for common issues and their corresponding solutions.

| Issue | Troubleshooting Steps | Solutions |

|---|---|---|

| Material degradation (cracking) | Visually inspect the clip for cracks, discoloration, or other signs of damage. | Replace the damaged clip with a new one. |

| Loose connections | Check the connections for proper tightening and alignment. | Re-tighten the connections or re-install the clip following the manufacturer’s instructions. |

| Environmental damage (corrosion) | Inspect for corrosion on the clip’s surface. | Clean the clip with a suitable cleaning agent. Consider using corrosion-resistant materials for future installations. |

Safety Considerations and Precautions

Working with zone of interest clips, while generally safe, requires attention to potential hazards. Understanding the potential risks and implementing appropriate safety measures is crucial for preventing accidents and ensuring a safe working environment. These clips, often used in precision applications, can pose specific dangers if not handled with care. Careful consideration of the materials, design, and operational procedures is paramount.

Zone of interest clips are a fascinating way to highlight specific details in a video, but the recent tragedy involving armorer Alec Baldwin on the set of “Rust” ( armorer alec baldwin rust shooting ) really puts things into perspective. Thinking about how crucial safety protocols are, even in seemingly simple video clips, makes me appreciate the importance of careful consideration when creating any visual content.

It’s a reminder that even seemingly small details can have significant consequences, especially when handling potentially dangerous situations, and that the zone of interest clip is still a powerful tool for focused storytelling when used properly.

Potential Hazards and Risks

Zone of interest clips, due to their precise nature and often high-strength materials, can present a range of hazards. Sharp edges or protruding components can cause cuts or abrasions. Incorrect handling techniques can lead to accidental slippage, potentially causing injuries. The clips may also be subjected to high stress levels during operation, requiring specific handling protocols to prevent unexpected failure.

Moreover, depending on the application, there might be exposure to chemicals or hazardous materials that necessitate appropriate safety equipment.

Safety Measures for Handling and Using Zone of Interest Clips

Implementing appropriate safety measures is vital when working with zone of interest clips. Always wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and sturdy footwear, to protect against potential injuries. Thoroughly inspect the clips for any damage or defects before use. Ensure the work area is well-lit and organized to prevent accidents. When handling clips, use proper gripping techniques to avoid slippage and maintain control.

I’ve been fascinated by zone of interest clips lately, particularly those that capture unexpected moments. Thinking about how important safety measures are in public spaces, especially in a place like Disney World, made me think about the recent disney world allergy death lawsuit. It’s a sobering reminder of the need for robust safety protocols in places where large numbers of people gather, and how important well-designed zone of interest clips can be in documenting these kinds of situations for further analysis.

If working with high-strength materials, follow manufacturer recommendations for safe operating procedures. Consider using specialized tools designed for handling specific types of zone of interest clips, further reducing risk. Proper training and awareness of potential hazards are essential for safe operation.

Table of Potential Hazards and Safety Precautions

| Potential Hazard | Safety Precautions |

|---|---|

| Sharp edges/protruding components | Wear safety glasses and gloves. Inspect clips for damage before use. |

| Accidental slippage | Use proper gripping techniques. Ensure a stable work surface. |

| Unexpected failure under stress | Follow manufacturer’s instructions for safe operation. Use appropriate handling tools. |

| Exposure to chemicals/hazardous materials | Use appropriate safety equipment (e.g., respirators, chemical suits). Consult Material Safety Data Sheets (MSDS). |

| Improper handling/operation | Follow detailed operating procedures. Seek proper training if needed. |

Comparison with Alternatives

Zone of interest clips offer a specific solution for precise positioning and control in various applications. Understanding their strengths and weaknesses, alongside those of alternative methods, is crucial for selecting the optimal approach. This comparison will explore alternative techniques, highlighting their advantages and disadvantages in comparison to zone of interest clips.

Alternative Positioning Methods

Zone of interest clips are not the only approach for achieving precise positioning. Several alternative methods exist, each with its own set of advantages and disadvantages. These include mechanical stops, magnetic hold systems, and programmable robotic arms. Choosing the right method depends heavily on the specific application’s requirements and constraints.

Mechanical Stops

Mechanical stops are simple and often inexpensive, relying on physical barriers to limit movement. Their primary strength lies in their straightforward design and ease of implementation. However, they often lack the precision and flexibility of zone of interest clips, particularly in dynamic or complex environments. Furthermore, they may be less effective in applications needing frequent repositioning or adjustments.

Magnetic Hold Systems

Magnetic hold systems provide a non-contact approach for securing components within a designated zone. Their advantage lies in their ability to maintain distance between the holding mechanism and the components, reducing wear and tear. However, magnetic forces can be susceptible to interference from external magnetic fields or variations in material properties, impacting precision and reliability. Furthermore, the strength of the magnetic field might not be sufficient for all applications requiring substantial holding force.

Programmable Robotic Arms

Programmable robotic arms offer the highest degree of flexibility and precision. Their ability to execute complex movements and adjustments based on pre-programmed instructions is a significant advantage. However, these systems are significantly more expensive and complex than zone of interest clips, requiring specialized programming and maintenance. They are generally more suited for high-volume production or highly intricate positioning tasks.

Comparison Table

| Feature | Zone of Interest Clips | Mechanical Stops | Magnetic Hold Systems | Programmable Robotic Arms |

|---|---|---|---|---|

| Precision | High | Low | Medium | Very High |

| Flexibility | Medium | Low | Medium | Very High |

| Cost | Medium | Low | Medium | High |

| Complexity | Medium | Low | Medium | High |

| Maintenance | Low | Low | Medium | High |

| Speed | Medium | Low | Medium | High |

| Examples of Use | Assembly lines, precise component positioning, automated manufacturing | Simple conveyor systems, fixed-position devices | Magnetic grippers in robotic systems, contactless component handling | Complex assembly tasks, automated welding, high-precision material manipulation |

Situations Favoring Alternatives

While zone of interest clips excel in many applications, there are situations where alternative solutions might be more suitable. Mechanical stops, for example, are a better choice for simple, fixed-position applications where high precision isn’t essential. Magnetic hold systems might be preferable in contactless applications requiring moderate precision and flexibility. Programmable robotic arms are best suited for intricate, high-volume production processes demanding maximum control and flexibility.

Future Trends and Developments

The field of zone of interest clips is poised for exciting advancements, driven by the ongoing quest for enhanced precision, efficiency, and adaptability in various applications. Emerging technologies are already demonstrating their potential to revolutionize how these clips are designed, manufactured, and employed. As the demands for these clips continue to evolve, so too will the innovative approaches to their design and functionality.

Potential Advancements in Design

Advanced materials will play a critical role in the future of zone of interest clips. Lightweight yet durable materials, such as high-strength polymers reinforced with carbon fiber, or specialized alloys, are likely to be incorporated. These materials will enable lighter weight designs without sacrificing strength and resilience, potentially leading to increased payload capacities or reduced overall system weight.

Furthermore, incorporating self-healing properties into the material could enhance durability and lifespan, reducing maintenance requirements and costs. Adaptive designs, incorporating smart materials or sensors, are also likely to become increasingly common. These designs could dynamically adjust to changing environmental conditions, such as temperature or vibration, automatically optimizing performance and ensuring consistent functionality.

Emerging Technologies

Additive manufacturing (3D printing) is poised to significantly impact the design and production of zone of interest clips. Complex geometries and customized shapes will become more accessible, allowing for tailored solutions to specific application needs. This technology also facilitates the creation of intricate internal structures for enhanced strength and functionality without the need for secondary machining processes. The integration of smart materials and sensors with 3D printing could create clips that actively monitor their own performance, adapting to changes in their environment, and even alerting users to potential issues before they arise.

Another emerging technology that will impact zone of interest clips is the use of nanotechnology, which could be applied to enhance the surface properties of the clips for improved adhesion or reduced friction.

Future Applications and Innovations

The applications for zone of interest clips are likely to expand beyond their current uses. One promising area is in the field of robotics, where zone of interest clips could be used for dynamic grasping and manipulation of objects with varying shapes and sizes. Similarly, advancements in bio-inspired designs are expected to yield clips with more complex functionalities.

Mimicking the properties of natural materials like bone or cartilage, for instance, could lead to clips that are both extremely strong and flexible, with potential applications in medical devices or prosthetics. Another area of innovation could be in the integration of wireless communication capabilities into the clips, allowing for real-time monitoring and feedback on their performance in dynamic environments.

Imagine a clip that not only holds an object in place but also provides real-time data on the object’s movement or stress levels.

Integration of Automation and Control Systems

Future designs will likely integrate automation and control systems into zone of interest clips. This could involve incorporating embedded microcontrollers or sensors that provide real-time feedback on performance and adjust parameters as needed. Real-time monitoring and control could allow for dynamic adjustments to the gripping force based on the characteristics of the object being held, leading to improved precision and safety.

Such integration will enable the development of more intelligent and adaptable zone of interest clips that respond dynamically to changing circumstances.

Final Review

In conclusion, zone of interest clips offer a powerful and versatile solution for a variety of applications. This detailed analysis has highlighted the historical context, technical specifications, and practical uses of these clips. Understanding the materials, manufacturing, and design considerations, along with the safety precautions, enables informed decision-making when choosing and using zone of interest clips. From engineering to photography to data analysis, their versatility and precision make them a valuable tool.

Top FAQs

What are some common materials used in zone of interest clips?

Common materials include steel, aluminum, and specialized polymers, depending on the application and desired strength/durability.

What are the typical dimensions of a zone of interest clip?

Dimensions vary greatly depending on the intended use and the size of the object being clipped. Specific dimensions will be dependent on the manufacturer and application.

How do zone of interest clips differ from other similar tools?

Zone of interest clips often excel in precision and controlled focusing, differentiating them from other tools that may offer less targeted engagement.

What are the safety precautions when handling zone of interest clips?

Always wear appropriate safety gear when handling, and be mindful of potential sharp edges or points. Consult manufacturer’s guidelines for specific safety precautions.